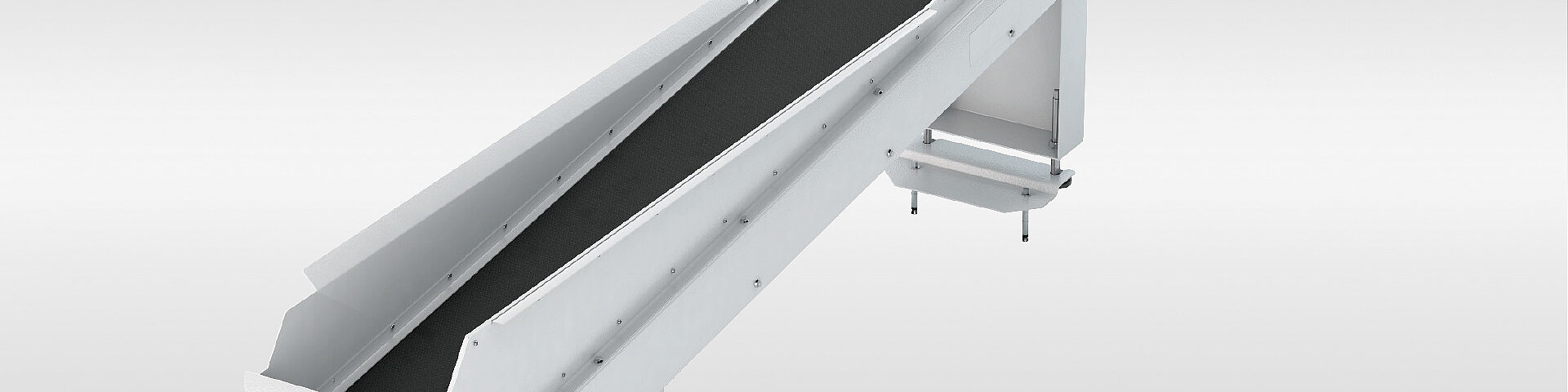

Belt conveyors

The all-rounders – also for parts with sharp edges

Our belt conveyors are predominantly used on punch-nibbling machines, for transporting punching scrap and punching trimmings. However, other parts can also be transported, such as waste parts from plastic injection machines. The transport belt of the conveyor is resistant to most oil and grease.

Structure:

- Housing made of sheet metal

- Convex return shafts

- Adjustable belt tension

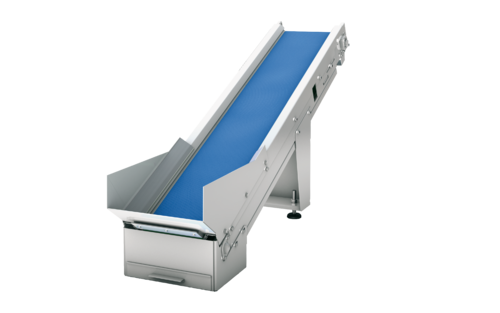

The parts conveyor for semi-finished and finished parts

This belt conveyor is predominantly utilized for transporting away semi-finished and finished parts. The deposit trough at the conveyor discharge is equipped with an insulating mat to protect the material being conveyed from damage.

The gentle transport solution for applications without accumulation of cooling lubricant.

- Also suitable for sharp-edged parts

- Special solution for parts with temperatures > 100°C possible

Standard dimensions

Type | HB | HK | BG | BK | FL max | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

GBF 113 | 40 | 134 | 250 | 450 | 650 | 850 | 1050 | 1200 | 1400 | BG + 70 | 12000 |

Deviating specifications on request

Explanation of terms:

BG = Belt width

HK = Box height

BK = Box weight

HB = Panel height

FL = Conveying length

HT = Hopper height

HU = Deflection shaft height

HA = Discharge height

α = Incline angle (maximum 30°)

All electrical components in CE design.

Additional local specifications on request. Please contact our support-team.