Hinged belt conveyors

Proven for a wide range of disposal tasks

Transportation of the material takes place on the upper trough of a revolving hinged belt. Carriers ensure transport of the material in the inclined section. For wet processing the cooling lubrications are collected in the conveyor housing and can be fed back into the machine circuit via an optionally available coolant tank or a pump station. Our hinged belt conveyors can be used either as stand-alone conveyors at machine tools, or as linked conveyor systems. Depending on the design, the material to be conveyed is brought to the required height at a defined incline and then discharged.

Structure

- Stable sheet metal construction

- Standardized housing cross-section with variable width

- Robust worm gear motor with torque arm

- Customized discharge height

- Customized incline standards – 30°, 45° and 60°

- Floor mounting or as a push-in version into the machine base

Dimensions of conveyor housing

Standard version

* The box height can be retracted on request.

Variable dimensions:

BSch = Hinged belt width

BK = Box width

BAG = Feed width

HB = Panel height

AAV = Distance between axles, vertical

LAG = Feed length

LAW = Discharge length

LG = Total length of the conveyor

α = Incline angle

Design-dependent dimensions:

HK = Box height

HKE = Retracted box height

LA = Length of the tail (discharge, incl. tensioning distance)

LU = Length of the tail (feed)

The tensioning station is located at the discharge.

| Type | HB [mm] | HK [mm] | HKE* [mm] | LAW min [mm] | LA [mm] | LU [mm] | ||

|---|---|---|---|---|---|---|---|---|

| SRF 040 | 40 | 60 | – | 140 | 110 | 350 | 180 | 73 |

| SRF 063 | 40 | 80 | 120 | 216 | 153 | 500 | 240 | 111 |

| SRF 100 | 150 | 250 | – | 360 | 260 | 850 | 600 | 185 |

| SRF 150 | 150 | 250 | 350 | 540 | 390 | 1000 | 600 | 275 |

All electrical components in CE design.

Additional local specifications on request. Please contact our support-team.

Dimensions of the hinged belt

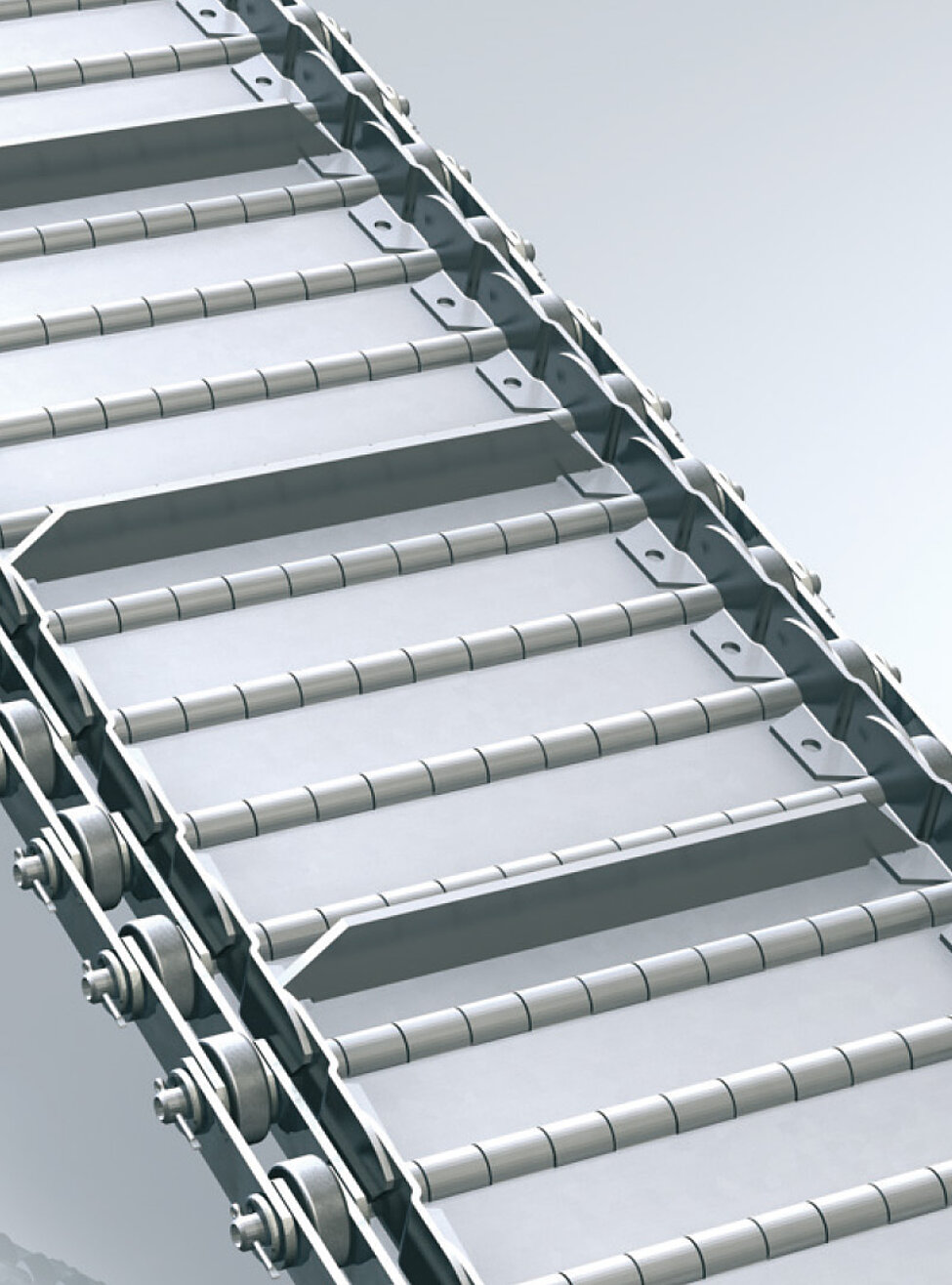

Manufactured of strip steel, the hinged belt plates have roller-formed hinge eyes, and are connected by means of axles to the side chains (which are designed as hollow pin chains), thus forming a hinged belt assembly.

| Type | t [mm] | SSCH [mm] | HS [mm] |

|---|---|---|---|

| SRF 040 | 40 | 1.5 | 20 |

| SRF 063 | 63 | 3 | 35 |

| SRF 100 | 100 | 3.5 | 60 |

| SRF 150 | 150 | 5 | 100 |

Definitions:

t = Pitch

BSch = Hinged belt width

SSCH = Plate thickness of the belt

HS = Height of the side board

BK = Box width

BAG = Feed width

Dimensions as a function of the hinged belt width

| Type | BSCH [mm] | BK [mm] | BAG [mm] |

|---|---|---|---|

| SRF 040 | 100 | 175 | 80 |

| 150 | 225 | 130 | |

| 200 | 275 | 180 | |

| 250 | 325 | 230 | |

| 300 | 375 | 280 | |

| 400 | 475 | 380 | |

| 500 | 575 | 480 | |

| 600 | 675 | 580 | |

| SRF 063 | 150 | 270 | 130 |

| 300 | 420 | 280 | |

| 400 | 520 | 380 | |

| 500 | 620 | 480 | |

| 600 | 720 | 580 | |

| 1050 | 1170 | 1030 | |

| 1650 | 1770 | 1630 | |

| 2100 | 2220 | 2080 |

| Type | BSCH [mm] | BK [mm] | BAG [mm] |

|---|---|---|---|

| SRF 100 | 150 | 300 | 120 |

| 300 | 450 | 270 | |

| 400 | 550 | 370 | |

| 500 | 650 | 470 | |

| 600 | 750 | 570 | |

| 1050 | 1200 | 1020 | |

| 1650 | 1800 | 1620 | |

| 2100 | 2250 | 2070 | |

| SRF 150 | 300 | 490 | 250 |

| 400 | 590 | 350 | |

| 500 | 690 | 450 | |

| 600 | 795 | 550 | |

| 700 | 890 | 650 | |

| 1050 | 1240 | 1000 | |

| 1650 | 1840 | 1600 | |

| 2100 | 2290 | 2050 |

Hinged belt designs

Various hinged belt designs are available for different operating conditions:

Hinged belt (standard)

for dry materials and chips with a low proportion of coolan

Hinged belt with perforations

for preseparation of coolant for materials with a high proportion of coolant

Hinged belt conveyor with corrugations

for transporting “sticky” parts

- Optimum chip leak tightness

- No attack surfaces for chips and stamped parts

- Robust design

- Prevents jamming of the conveyed material